Central Gas Pipeline System

Central Gas Pipeline System Specification

- Equipment Type

- Central Gas Pipeline System

- Material

- Mild Steel, Copper, Brass

- Condition

- New

- Portable

- No

- Disposable

- No

- Wall Mounted

- No

- Waterproof

- No

- Noise Level

- Silent Operation

- Sound Prompt

- No

- Operating Type

- Automatic/Manual

- Power Source

- Electric/No Power Required Depending on Section

- Voltage

- 220-240 V (Control Panel, Optional)

- Power Consumption

- Minimal (Control Panel, Optional)

- Dimension (L*W*H)

- Customized as per project site

- Weight

- Varies as per installation

- Color

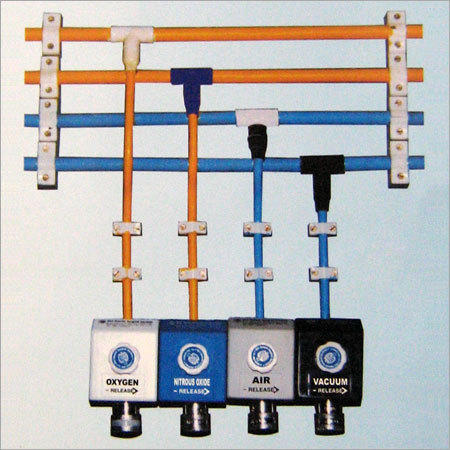

- Silver, Yellow, Blue (Pipes and Markings)

- Usage

- Medical/Industrial Central Gas Distribution

- Mounting

- Ceiling, Wall Bracket, or Floor Mount

- Number of Outlets

- Custom Configurable

- Surface Finish

- Epoxy Powder Coated or Electroplated

- Flow Meter Compatibility

- Yes

- Pipeline Insulation

- Yes (Optional)

- Line Pressure Range

- 4-7 bar (Standard for Medical Gases)

- Safety Features

- Pressure Relief Valves, Area Alarm Panels, Non-return Valves

- System Components

- Zone Valves, Terminal Units, Alarm Panels, Medical Gas Manifolds

- Gas Types Supported

- Oxygen, Nitrous Oxide, Medical Air, Carbon Dioxide, Vacuum, etc.

- Installation Area

- Hospitals, Laboratories, Industrial Facilities

- Pipe Size

- Varies (Common: 15mm, 22mm, 28mm)

- Maintenance

- Easy Access for Service and Inspection

Central Gas Pipeline System Trade Information

- Main Export Market(s)

- Central America, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Australia, Africa

- Main Domestic Market

- All India

About Central Gas Pipeline System

The Central Gas Pipeline System is an important network of infrastructures that ensures the delivery of natural gas over long distances. This sophisticated system comprises pipelines, compressors and control stations that ensure a smooth flow from source points to delivery centers. It ensures a steady supply of natural gas to the residential and commercial sectors as well as industries with zero risk of accidents. The crucial contribution of the Central Gas Pipeline System in meeting modern societys energy needs is provided through its efficiency and reliability.

Versatile Gas Distribution for Multiple Sectors

Our Central Gas Pipeline System efficiently caters to hospitals, laboratories, and industrial facilities needing reliable distribution of medical and industrial gases. With support for oxygen, nitrous oxide, medical air, carbon dioxide, and vacuum, it ensures continuous and safe supply tailored to each sites unique requirements.

Safety and Compliance at the Core

The pipeline system integrates critical safety features such as area alarm panels, pressure relief, and non-return valves. All components meet rigorous medical and industrial standards, backed by quality materials like mild steel, copper, and brass, to safeguard both users and facilities.

Flexible Installation & Maintenance

Designed for adaptability, the system offers ceiling, floor, or wall bracket mounting. Outlet numbers and pipe dimensions are customizable, while thoughtful engineering guarantees easy access for maintenance without operational disruption. Flow meter compatibility further enhances monitoring and control.

FAQs of Central Gas Pipeline System:

Q: How is the Central Gas Pipeline System installed in different types of facilities?

A: This system is customizable for a range of applications such as hospitals, labs, and industrial sites. Installation can be configured for ceiling, wall bracket, or floor mounting, and all dimensions are tailored to the specific project. Expert teams ensure optimal setup according to safety standards and facility layout.Q: What gases are supported by the Central Gas Pipeline System?

A: The system supports a variety of gases including oxygen, nitrous oxide, medical air, carbon dioxide, and vacuum. It can also be adapted for other medical or industrial gases based on client requirements.Q: When should pipeline insulation be considered?

A: Pipeline insulation is optional and generally recommended for environments with extreme temperature variations or where condensation and energy efficiency are concerns. It helps in maintaining gas purity and prevents thermal losses.Q: Where are the systems safety features integrated?

A: Safety features such as pressure relief valves, non-return valves, and area alarm panels are installed at critical junctures like terminal units and control areas. These devices work together to monitor and maintain optimal operational safety throughout the pipeline.Q: What is the process for routine maintenance and service?

A: Routine maintenance is facilitated by the systems design, which offers easy access to vital components like zone valves, alarm panels, and manifolds. Regular inspection schedules and minimal disruption procedures are provided for ongoing reliability.Q: What are the major benefits of using a centralized gas pipeline system?

A: A centralized system ensures continuous, uninterrupted gas supply, improved safety, better resource management, and reduced operational costs. It supports seamless monitoring and easy maintenance, transforming facility gas distribution into a secure and efficient process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

We accept only bulk quantity orders.

Send Inquiry

Send Inquiry